PMD INFORMATION & TROUBLESHOOTING

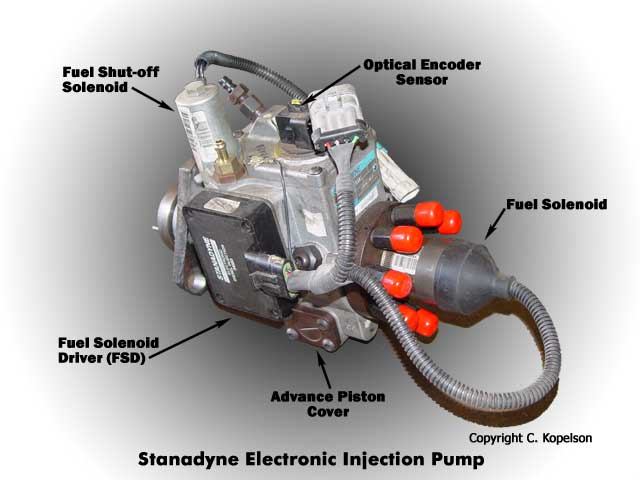

The GM 6.5 Diesel PMD/FSD fior the Stanadyne DS-4 Injection Pump is a signal intensifier - the engine PCM sends a signal to the PMD which is then amplified by a pair of 500 Watt transistors as Pulse Width Modulation to control the fuel solenoid opening amount. This amplified signal then acts as a driver for the fuel solenoid. The PMD is mounted to the driver side of the Stanadyne DS-4 injection pump centered in the valley at the front of the engine. It is extremely hard to reach on a van engine - and one can still however use a long THIN screw driver to side in and unlock the cable clip and then fish it out with a coat hanger bent with a small hook on the end.

If you drive a GM 6.5 Diesel, there are a few "spare parts" you should always keep in your vehicle - yeah its crazy but when a part fails you'll be glad you did

1. A spare fuel lift pump - and not the OEM type. See https://bigbay4bestbuys.com/Sure_Cure_GM_6_5_Lift_Pump_Solution_Kit

[ You can opt out of Google Ads if you are a registered user at /ad-options ]2. A spare PMD - with possible a spare pigtail connector - the power lead gets hot and may loose temper and fail to hold a tight electrical connector

3. A spare vacuum pump - the bearings seize unexpectedly, or the diaphragm tears and then you have int he first instance a serpentine belt that will burn being dragged across the seized vacuum pump pulley and surely shred - so you should stop immediately and replace it it it seized where ever you are. If the PMD is relocated where we show it below - you could also cut the umbilical to the PMD as relocated. If the diaphragm just tears you will loose boost and lots of black smoke with result. Of COURSE you also need to have the pulley puller too - A three foot length of fresh hose for the inital vaccum line as the old or original one it likely to be hard or the OEM one is simply plastic tubing which is guaranteed to be brittle and hard. Harborfreight sells THREE of these pullers for about $20.00. See https://www.harborfreight.com/three-jaw-puller-set-3-pc-63953.html

4. A spare belt - because if you shred it - you'll overheat fast,and/or punch a hole in the radiator and/or damage the transmission line or oil cooler line, and you will have nor power steering or brakes - and of course no alternator

5. A spare rebuilt Injection Pump. If the optical sensor goes you will go into limp mode and it will run like crap - indeed if at all - and the optical sensor alone is a 250 to 300 dollars part,, and if you have been abusing it with lower fuel pressure, the fuel solenoid if it burns out - is not field fixable - and there is no throttle pedal response or worse the IP may let the engine runaway. It is a $500 best case spare part - but if it fails either way it will mean a tow and possibly a mechanic who does not know how to replace it anyway. They are not hard to replace even in the field at the side of the road. About two to three hours

Of curse you need to carry tools to do all of this

By design, the flow of diesel fuel through the injection pump is intended to cool the PMD, which produces and must dissipate a significant amount of heat of BOTH the IP itself and the PMD especially if your inlet pump pressures are so low the Fuel Solenoid has to hold the throttle plate open with any extended duty cycle.

If there are sufficient IP pump INLET fuel pressures - then the top cavity of the IP is full of recirculating fuel and that fuel flow is a cooling medium is believed to be effective under most all conditions, but fails to provide sufficient cooling in relatively high ambient temperatures. As shown above it is a large tank area, but it also does not address the heat soak effect experienced when an engine at operating temperature is shut down. The repeated heating and cooling cycles experienced by the PMD and its inability to dissipate heat in certain conditions is generally accepted as the leading cause of PMD failures. But the REAL root cause is the low pressures of the lift pump causing the PMD to have extended duty cycles - when under normal conditions the IP actually pushes the throttle open in lock step with teh engine RPM.

The duty cycle of the PMD increases with engine RPM; IF THE INLET fuel pressures are too low, and the occurrence of injection events with respect to time increases with engine speed and thus the PMD will receive and amplify signals from the PCM at a greater rate. with adequate fuel pressures - the throttle is actually "pushed" open by the fuel pressure going to the injectors, and it is closed by a spring without that slight tug on it.. This is a feature set with a dial indicator and a crush washer one time when the IP is built, and if not done right the IP will let the engine runaway with rpm

The PMD/FSD also contains a "calibration resistor" within the connector of the module. When the wiring harness connector is inserted into the PMD connector, the resistor becomes wedged between the two. Calibration resistors relate to the maximum fuel flow rate and are available in ratings #1 - # 9, with #9 being the highest calibration available. A #5 calibration resistor is often considered the average size. These resistors can burn out on the trace - or pop open and many places mount the resister externally in the cable itself.

Replacement of the PMD requires removal of the entire intake manifold, a somewhat burdensome task to simply reach the module's 4 mounting bolts and single electrical connection. A highly recommended solution is to abandon the original PMD altogether, replacing and relocating it to a more suitable (and accessible) location. For those who want to go a step further, the aftermarket produces various options that both relocate and add a heat sink to the PMD. One such kit is being used in the procedures below...

GM experienced widespread PMD failures, leading them to warranty the injection pump on the 6.5L diesel for 100,000 miles in order to maintain the support (and business) of their patrons. But it was not the PMD's which were failing - it was because GM used a lift pump that NEVER DID WORK for long at the pressures the IP required to operate properly.

You may have read the IP only needs 5 psi to work - and that it can "suck" fuel - and that that is absolutely not the whole truth - it needs 10 to 12 psi to work properly and be internally lubricated - and the 5 psi number is the MINIMUM operating pressure at IDLE or Wide Open throttle to operate without damaging the system internally or electrically.as set by Stanadyne in the test procedures they set for pump rebuilds

Symptoms of a failing PMD include, but are not limited to: hard starting/excessive cranking to start an engine, engine stalling, engine misfires, and ultimately a no start condition when the PMD has failed altogether. It can fail on a crank of the engine, meaning you can shut it off and then try to restart - and nothing works. An engine that will not restart after being shutdown at operating temperature but will restart after it has had time to cool is an extremely common sign that a PMD is failing and should be replaced. Engine misfires have been known to be caused by a failing PMD, however this is somewhat rare and a misfire condition is often due to other fuel system related problems, including a faulty lift pump or oil pressure sensor (on 95+ engines, because the electrical load for the lift pump is carried through the oil pressure sensor on those early engines.).

Diagnosing a PMD is an art as much as it is a science; if you are experiencing any of the aforementioned problems and the PMD has not been relocated, replacing and relocating it is a wise investment. If it does not alleviate drive -ability issues, you have, at the very least, reduced or eliminated PMD concerns for the foreseeable future. For misfire related problems, a complete fuel system diagnosis is recommended before replacing the PMD - this should include fuel injectors, the fuel filter, the lift pump, and the oil pressure sensor (on applicable model years). Bucking/jerking under load often points to a lift pump and/or oil pressure sensor failure and not a PMD related issue. The best thing is not to even mess around with the OEM lift pump and replace it with a Sure Cure Lift Pump

FSD/PMD RELOCATION & REPLACEMENT

Click any thumbnail to view high resolution, full size image w/ details or right click and open in new window on the image

• Disconnect both negative battery cables.

• If applicable, remove the plastic "Turbo Power" engine cover (4 bolts, 13 mm socket).

• Locate the PMD/FSD on the driver side of the injection pump, which is mounted toward the front of the engine in the valley between the intake manifold runners.

• Disconnect the PMD/FSD connector - it is located at the rear of the PMD (towards the cab). The connector retaining clip is accessible by using a long flathead screwdriver to release the clip, and a second screwdriver (or long nimble fingers) to pull the connector towards the firewall. Do not tug or place strain on the wires in order to remove the connector.

• Maneuver the connector upwards. A section of solid core electrical wire bent into a hook works well to grab the connector.

• Disconnect the FSD/PMD ground wire using a T25 Torx bit. It's a tight fit, but a 1/4" drive bit and ratchet can reach the bolt after pushing the fuel line aside gently.

• Attempt to pull the connector and wiring pigtail outwards; if the wires do not budge, you will need an extension pigtail. If you are able to free 4"-6" of slack, you should be able to reach the relocated PMD (if relocating to the same position as us). It is hit-or-miss whether or not you'll need an extension pigtail; often, the harness connector gets hung on one of the injector lines. An 3 to 6 extension is all that is necessary if you are unable to pull the harness outwards. Note - if using an extension, do not remove the ground wire - simply leave it attached to the injection pump.

The 6 ft extension harness may be used to relocate the PMD in a variety of positions. But the best is right at the crack of the hood in the coolest air flow. DO NOT mount it on top of the engine. A hinge like this makes it easy to flip up the PMD to swap it

• Install the relocated PMD/FSD. In our case, the PMD and heat sink mount to the upper intake plenum. Removing the intake plenum bolts requires a 10mm socket.

• If you're NOT using an extension pigtail (i.e. using the factory connector because you were able to obtain enough slack) attach the PMD ground wire to the heat sink.

• Verify that you're new PMD/FSD has the calibration resistor installed. If there is no calibration resistor, you will need to purchase and install one. The calibration resistor relates to fuel flow and is installed in the connector on the PMD.

• Install the PMD harness connector to the PMD or install the extension pigtail between the PMD and factory PMD harness.

Our relocation kit includes the heat sink and hinge as shown above with three self tapping screws you can mount loosely in a drill and run in carefully, and a short extension cable with a built in resistor and a 66 inch cable to reach the hood area